Upgrade to Eight

Carrier Counts

Have you counted the fibers in your braided line recently? Yeah, me neither. But even if the naked eye can’t identify different carriers woven together to create polyethylene (PE) fishing line, thread count still matters. Just like men’s suits and bedsheets, right?

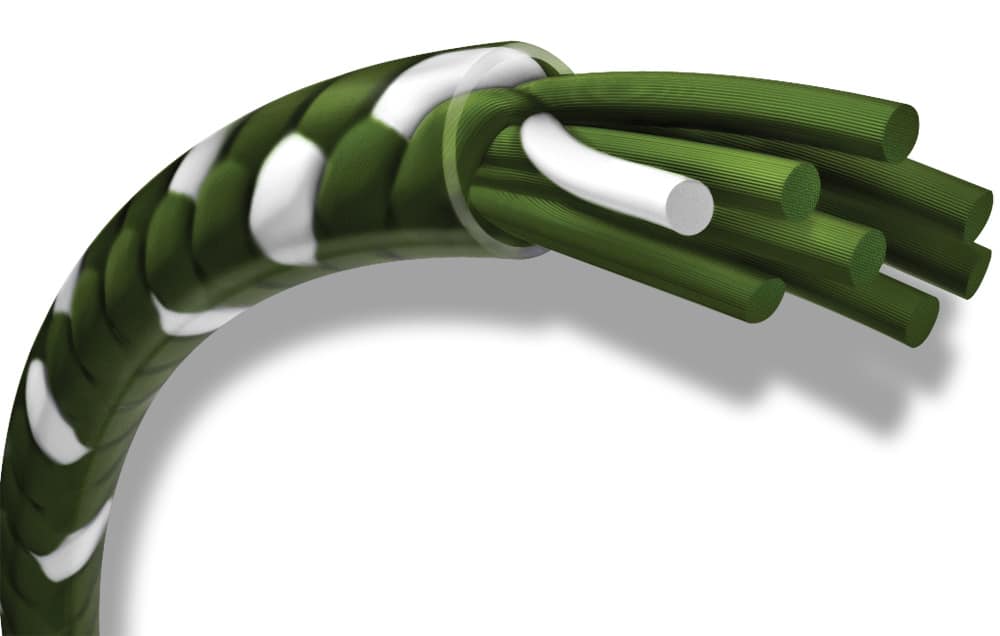

Consider how braided fishing line is constructed. Polyethylene microfilaments are gel spun (spun together while in partial-liquid form, producing a stronger interchain connection) to create carriers — or strands — often under trade names Dyneema or Spectra. The term “carrier” is sometimes replaced with “end” or “yarn” in braided-line parlance. What’s misleading about the braid moniker is that carriers are actually woven together (a small but specific difference some manufacturers pointed out to me) to create braided line, forming what’s known as “pics” at points where they intersect.

For example, Sufix 832 line stands for 8 strands and a pic count of 32 per inch.

“Spurred on by interest for eight-carrier braids, producers continue to make smaller polyethylene yarns,” says Dave Burch, president of FINS fishing. “Anglers want thinner and thinner lines for better reel capacity and castability, but the cost is higher for the manufacturer.”

The polyethylene used in braided fishing line is almost all chemically identical — the only difference is in the bundles of microfilaments that make up the yarn. Manufacturers’ PE microfilaments might measure differently, say 50 or 100 denier. Denier is a measurement unit for the fineness of yarn, equal to about one single strand of silk.

“Let’s say a particular braid requires 800 Dyneema microfibers to reach a certain strength,” says Clay Norris, senior product manager at Berkley Fishing. “It can be created by a four-carrier braid with 200-denier microfilaments or an eight-carrier with 100-denier microfilaments. Both are the same strength, but the eight-carrier is smoother and rounder since the individual fiber bundles are smaller.”

Eight-Carrier Advantage

“Four-carrier is like an off-road tire, able to cut through weeds with rigid strength and brute force,” says Ted Thibault, TUF-Line‘s global sales manager. “Eight-carrier is like a highway tire, with less noise and less friction when used. The four-carrier works well for bottomfishing, while eight-carrier casts better.”

Eight-carrier “fully occupied” braids are also known as diamond braids because of their two-over, two-under construction. The higher carrier braid is smoother and more supple than four-carrier “half-occupied” construction, commonly referred to as basket braid. Basket construction is a one-over, one-under weave, recognized by nubs on the line’s surface, producing a familiar singing noise when cast through the rod guides. Hold four-carrier and eight-carrier braids in your hand, and you can identify each type by feel alone.

“Basket-braid construction typically has more fiber integration, so yarns are held firmly in the line structure for better abrasion resistance,” says Konrad Krauland, founder and president of PowerPro. “The eight-end diamond braids are smoother due to their twill construction, plus quieter through the guides, and more sensitive during the retrieve.”

Four- and eight-carrier braids can actually be made on the same machine. Basket braids are made by taking out half the carriers, hence the term “half-occupied.” Diamond braids are typically fully occupied machines, meaning that each position on the braider has a carrier.

“That is not to say that eight-end braids will always be diamond braid,” says Krauland. “It is possible to [construct] eight-end basket braid by removing half the carriers from a 16-carrier braiding machine.”

The shortcoming with diamond braid is that it is more likely to bury. Typically, basket braid with a better, solid cross section is more cylindrical and resistant to burying into itself in the spool. The eight-carrier constructions are also more expensive than four-end offerings because of the higher cost of the smaller denier yarns.

Fishing Eight

“Eight-strand braid creates a smoother, quieter and rounder surface that casts farther,” says Dan Quinn, field promotions manager at Sufix’s parent company, Rapala, “plus it still retains abrasion resistance, knot strength and tensile strength. I believe that one main reason four-carrier is still around is because of the cheaper price difference.”

There are situations where a less-expensive four-strand line still might have advantages.

“Here on the West Coast, some of our calico bass fanatics like to run 60- to 80-pound four-strand as a ‘kelp-cutter’ rig,” says Mark Smith of Toro Tamer. “With the four-strand line and a short top shot of leader, fishermen can cut their way out of kelp and fish heavier cover, targeting larger bass.”

Surf-casting, tossing surface iron or fishing live bait might require a smoother-casting line such as the eight-strand braids.

“Different fishing applications demand different lines,” says Smith. “Not all braided lines are produced the same, and better suppliers target their offerings to match specific applications.”

For inshore applications, such as fishing with jerkbaits or topwater or soft-plastic fishing with fluorocarbon leader, Seaguar’s assistant marketing manager Brian Evans recommends eight-strand. “I feel like four-strand shines anywhere you have to fish in heavy grass, cover or mats, and need a line that cuts through the vegetation,” he says.

Next Gen

The jump from four to eight carriers has obvious benefits, so can anglers soon expect 12- or 16-carrier braid that’s not hollow-core?

“Sixteen-strand would be incredibly round and castable, but with so many fibers, the line would have a tendency to cut itself, flatten out, and have far less abrasion resistance,” says Quinn, “as well as cost roughly three times more than an eight-carrier to produce.”

Indeed, 16-carrier might be cost prohibitive in uses besides specialized hollow-core braid applications, points out Thibault. Most current hollow-core braids are 12- or 16-strand construction, but their use remains with anglers who need splicing and finger-trap style connections. Instead, manufacturers might research and utilize materials with finer denier to replicate the castability characteristics.

Burch believes he might have the next evolution in braid with FINS’ latest nine-carrier 40G product. “The center of the line is Spectra High Tenacity fiber with eight ends of PE wrapped around it,” he says. “Spectra HT is 25 percent stronger and 30 percent smaller than traditional deniers of Spectra fiber. It is the smallest diameter-to-strength ratio we have ever offered.”

Don’t be surprised to see more combinations of different fibers blended with polyethylene in the future.

Sufix’s 832 brand utilizes a piece of hydrophobic Gore fiber, along with seven PE fibers, to provide high strength and water repellency. Mixing and matching fibers works. Burch utilizes Spectra’s HT fiber to decrease the 40G’s diameter even further than traditional braids; his 5-pound-test has the diameter of 1-pound mono and an average breaking strength closer to 20 pounds.

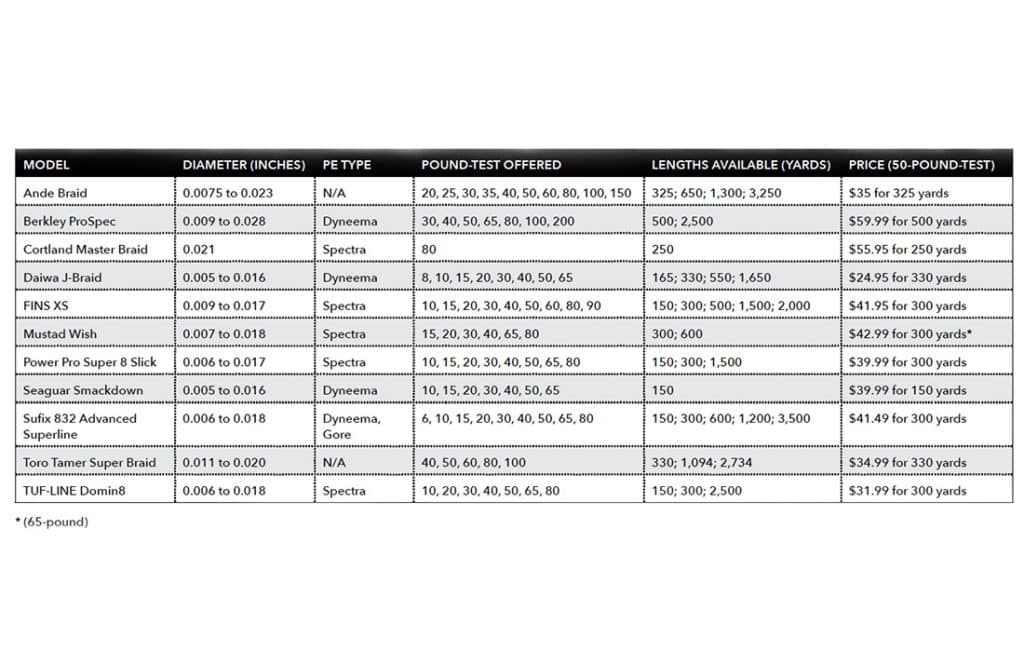

Comparing Different Eight Carriers

Which Fishing Lines Test the Strongest?